ABOUT US

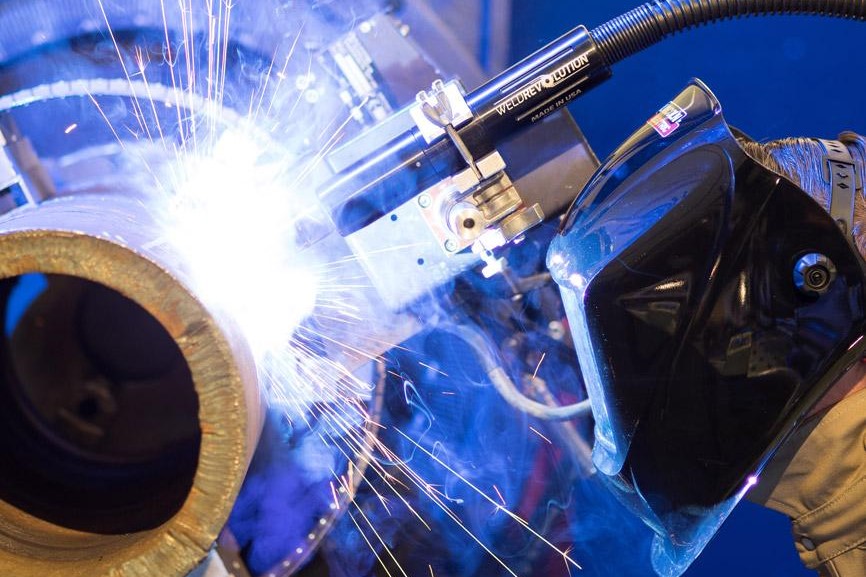

Welcome To Laser Welding Limited

We have been in business since 2005 starting in Drury, South Auckland. Moving to our current sight in Manukau City in late 2006. During this time we have seen a steady increase in the development of the business. In 2008 we took delivery of a second machine which allowed further growth. In early 2010 we modified the second machine to handle much larger jobs. This new capacity has been used enthusiastically by customers.